How to Finish a Cornhole Board (2022)

We often get asked questions about finishing DIY cornhole boards with different products, particularly polyurethane.

Before we get into this article, I feel it is important to note that we do not recommend putting any product on our already printed boards from Slick Woody’s Cornhole Company. Our boards are designed with a playing surface that will be consistent and durable regardless of weather, humidity, and other circumstances. We also offer cornhole board wraps, meaning you do not have to finish and seal yourself!

With that all being said, we feel it is important to help provide an understanding for our supporters and cornhole players around the world alike when it comes to finishing cornhole boards.

In this article, we will be talking about what polyurethane is, how to properly apply it to a cornhole board, and a common alternative to polyurethane.

What is polyurethane?

The traditional definition states that polyurethane - often referred to as poly - is a plastic material that exists in various forms. It can be tailored to be either rigid or flexible and is the material of choice for a broad range of end-user applications. You can find half pints of polyurethane at your local home goods store for anywhere between $5 to $10.

As far as cornhole boards go, polyurethane provides an opportunity to give your boards a coat of protection and a slicker surface. Polyurethane can be oil- or water-based, which can affect the time it takes to dry. An oil-based solution will take longer to dry than a water-based solution.

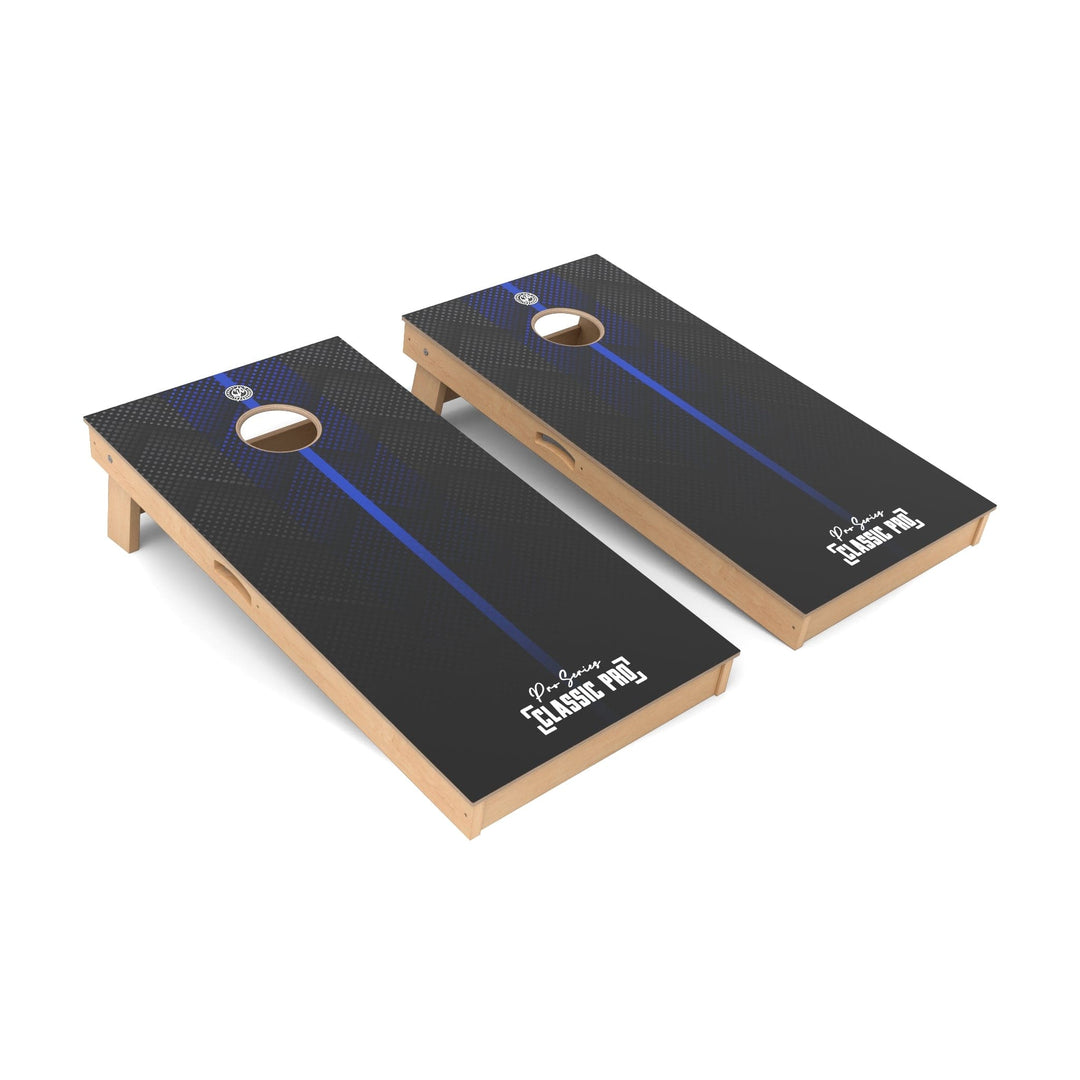

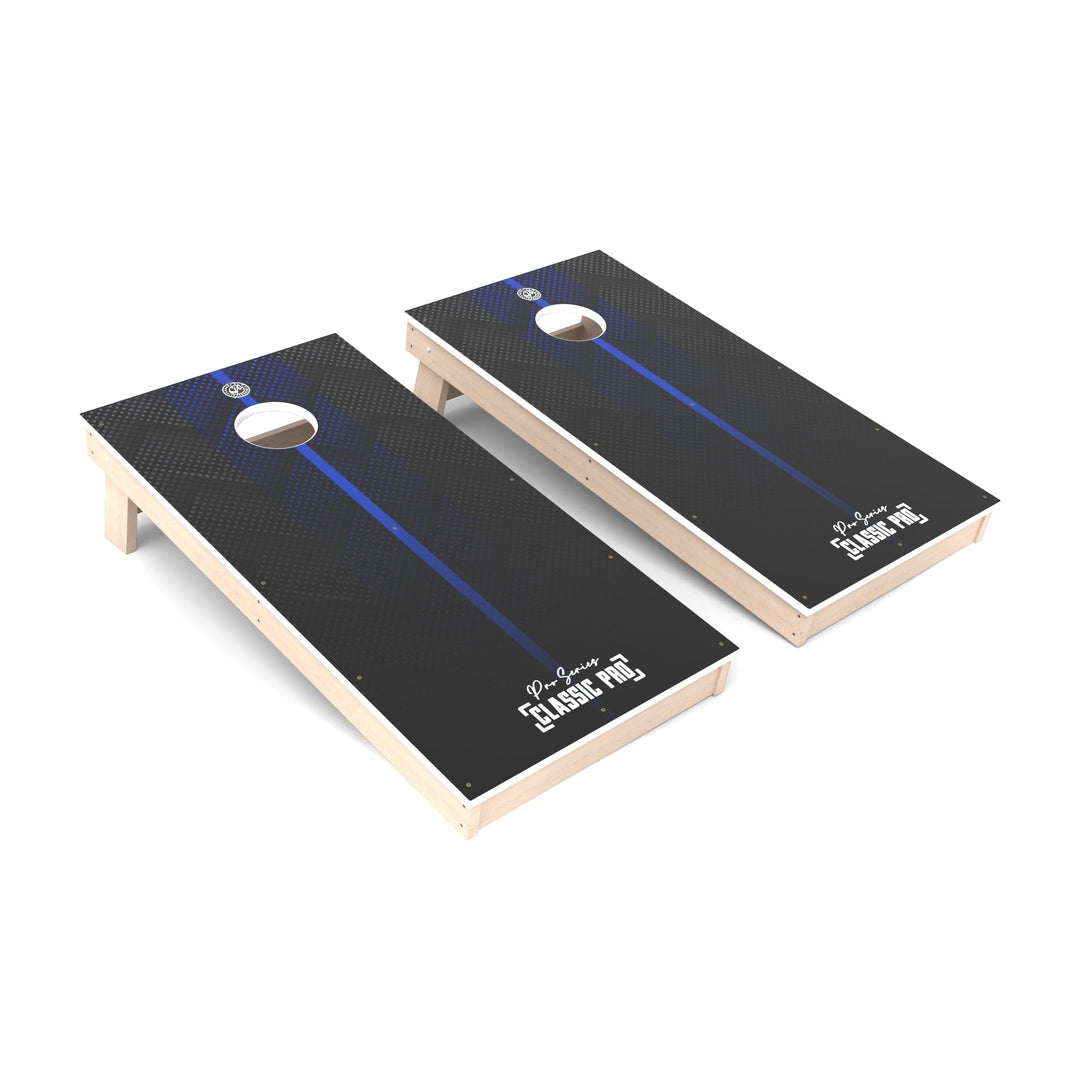

Using polyurethane can be an effective way to protect your boards for years to come. Oil-based polyurethane often leaves an amber glow on top of unfinished cornhole boards, whereas water-based poly will leave a more clear coat. Oil-based is also a more durable substance. You can see the difference in color from an oil-based poly below.

(The cornhole board on the left has been finished with oil-based polyurethane)

How to Apply Polyurethane to a Cornhole Board

When it comes to applying polyurethane to your cornhole board, you want to first make sure that you have the proper items on hand. Your list of items should include:

- A container of oil- or water-based polyurethane

- A foam brush or paint brush

- Sandpaper (320 grit or higher)

To start off the application process, lay down a tarp or similar surface to keep your working area clean. Make sure to wipe down your board and keep it clean of debris before beginning to apply your poly. Be sure not to use a paint roller, since a roller can create air bubbles.

Open your can of poly and begin to apply it onto the board using vertical strokes. Try your best to make sure you don't miss any spots, as it can affect the playing surface of the board going forward.

Don’t forget to add poly to the sides of your boards and the legs. Many people often apply only a few coats to these areas.

Five to ten coats of poly (with a few hours of drying time between each coat) are usually recommended for your cornhole board. To help your coats dry faster, you can consider using some type of ventilation. It is best to wait 20 minutes after applying a coat to use a fan so air bubbles do not form.

After you have applied all but the last coat, gently sand the surface of your boards. Use a fine sandpaper (320 grit or higher) to smooth the surface of your boards. Try to avoid sanding over any decals.

Alternative Finish for Cornhole Boards

Although polyurethane is the most asked about product when it comes to finishing cornhole boards, polycrylic is also a commonly used coating by cornhole players.

Polycrylic is a fast-drying, water-based clear coating that protects the surface of your board and adds a little slide. This coating will leave a glossy look to it and usually takes less than two hours to dry. The polycrylic finish can be great for protecting decals, paint, or any other artwork, as well as any unfinished wood.

When using a polycrylic finish, it is best to apply it with a synthetic bristle brush if you are manually painting the coat on. Or, you can use a polycrylic spray which can help avoid any brush marks.

The coating should protect your cornhole boards from common abrasion, scuffing, chipping, water, alcohol, and other household chemicals. The application process only requires two or three coats to be added to your boards.

Whether you are manufacturing your own boards, putting together a DIY board, or want to modify one of your existing boards, it can be a huge help understanding the effects of coating your board and the process that goes along with it. Cornhole boards provide a source of entertainment and fun, so they should be properly treated and taken care of to make sure they will last for years to come.

Polyurethane and polycrylic are both great choices when it comes to finishing your cornhole boards. The application process for both substances can be applied and finished within 24 hours and ready for use by the next day.

Finishing your boards can be a simple and inexpensive way to protect and stain your cornhole boards while adding a bit more slickness to them.

Also, be sure to check out our cornhole board wraps! Be sure to send a message through the messenger button if you have any questions!